Introduction

Our wheel stud conversion kits offer the following features and benefits:

- Faster wheel installation as the studs make it easy to line up the wheel on the hub

- Peace of mind knowing that studs are a safer way to ensure proper wheel-to-hub contact

- No more need for a wheel hanger to mount wheels

- You can easily add wheel spacers within the range of the stud length

- Avoid costly repairs to the bolt holes in the hubs from constant removal and installation of lug bolts

- Simple kit installation

Converting your vehicle to wheel studs and lug nuts is a rewarding project that can be completed in an afternoon. Say goodbye to threading wheel hangers in and out and fighting to line up the lug holes. Before you begin, please read and familiarize yourself with these instructions and make sure you have all the required tools on hand. Thank you for purchasing our wheel stud conversion kit. We appreciate your business!

Wheel Stud Conversion Kit Contents

Required Tools

NOTE: These instructions are meant to be used as a general guide for installing a Wheel Stud Conversion Kit on all makes and models. Below is a list of the tools we offer at ECS Tuning which may be required during this install. Please consult your Owner’s Manual or service information to confirm your lug size, thread pitch, and other information before beginning the installation.

• Protecta-Sockets (for lug nuts) ES#2221243

• 3/8”Drive Ratchet ES#2765902

• 3/8” Drive Torque Wrench ES#2221245

• 1/2”Drive Breaker Bar ES#2776653

• 1/2” Drive Torque Wrench ES#2221244

• Wheel Hanger – M12x1.5 ES#2636265

• Wheel Hanger – M14x1.25 ES#2678092

• Wheel Hanger – M14x1.5 ES#2636260

• Hex Head Allen Bit Socket: 5mm ES#11420

• 3/8” Drive Extensions

Shop Supplies and Materials

• Hand Cleaner/Degreaser ES#2167336

• Low Boy Lightweight Aluminum Jack ES#240941

• Aluminum 3-Ton Jack Stands ES#2763355

Installation Notes

- RH refers to the passenger side of the vehicle.

- LH refers to the driver side of the vehicle.

- Always use the proper torque specifications.

- If applicable to this installation, torque specifications will be listed throughout the document and at the end as well.

- Please read all of these instructions and familiarize yourself with the complete process BEFORE you begin.

General Preparation and Safety Information

ECS Tuning cares about your health and safety. Please read the following safety information. This information pertains to automotive service in general, and while it may not pertain to every job you do, please remember and share these important safety tips.

- Park your car in a safe, well lit, level area.

- Shut the engine off and remove the key from the ignition switch.

- Make sure any remote start devices are properly disabled.

- ALWAYS wear safety glasses.

- Make sure the parking brake is applied until the vehicle is safely lifted and supported.

- If using an automotive lift, be sure and utilize the factory specified lift points. Lifting a vehicle in an incorrect location can cause damage to the suspension/running gear.

- When lifting a vehicle using a jack, always utilize the factory specified lift points. Lifting a vehicle in an incorrect location can cause damage to the suspension/running gear. ALWAYS support the vehicle with jack stands.

- ALWAYS read and follow all safety information and warnings for the equipment you are using.

Never get underneath a vehicle that is supported only by a jack. Always make sure that the vehicle is securely supported on jack stands.

Conversion Kit Installation

Step 1:

19mm Socket, 1/2” Breaker Bar

Prepare to raise the vehicle, but leave the wheels in contact with the ground. If you are removing lightweight aluminum lug bolts as we are doing here, we prefer to break them loose by hand. An impact wrench can be used for removal of steel lug bolts, but if you do not have one, break them loose by hand before raising the vehicle.

We are performing this installation on a Porsche 996 equipped with OEM Porsche 997 wheels, some details such as lug nut size and torque specifications will vary from vehicle to vehicle.

Step 2:

Wheel Hanger

Raise and support the vehicle and remove the wheels. We are using a wheel hanger here to prevent the risk damage, but if you do not have one, don’t worry you will never need one again after this installation.

Step 3:

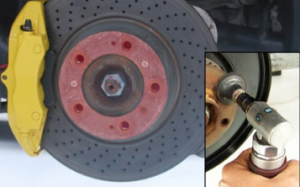

This is the perfect time to clean any corrosion from where the wheel meets the hub (this area is highlighted RED in the photo). An abrasive disc attached to a drill or die grinder can be the fastest way to remove all of the heavy scale from the hub, but a brush can also be used by hand if power tools are not available.

Be sure to clean out the lug stud holes out with a wire brush or similar tool, removing any rust, corrosion or grease. This will allow the Loctite to adhere properly when installed.

Step 4:

Blue Loctite

Install all of the new studs on one wheel at a time. Start by applying Blue Loctite to the short threads on the stud as shown in the photo.

Only apply the Blue Loctite to the short side of the stud which is threaded into the hub, this keeps the stud in place when loosening the lug nuts. DO NOT apply Loctite to the long side of the stud or the lug nuts will be extremely difficult to remove.

Step 5:

Thread all of the studs in by hand, making sure the stud threads easily through the lug holes in the rotor hat.

If the shoulder on the stud does not clear the lug holes in the rotor hat, or binds up before it is completely installed, please make sure your application is correct.

Step 6:

5mm Allen Socket, Torque Wrench

Tighten all of the studs to 15 Nm (11 Ft-lbs).

This step may require another person to push down on the brake pedal while you are torquing the studs.

Step 7:

Repeat steps four, five & six on the remaining wheels.

Step 8:

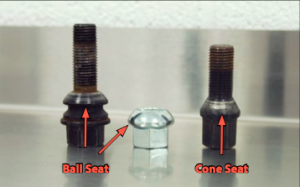

Please note: There are several different types of lug nuts as shown in the photo. The lug bolt on the left and the lug nut in the middle have a “ball seat”, and the lug bolt on the right has a “cone seat” (or “tapered seat”). Please inspect your lug bolts closely to be sure you select the correct lug nuts for your wheel application.

Step 9:

19mm Socket, Torque Wrench

Install all four wheels onto the vehicle and torque all of the lug nuts to the proper torque specified by the vehicle manufacturer.

Step 10:

Your Wheel Stud Conversion Kit installation is now complete!

Interested in purchasing? Click HERE to shop now!

Proper service and repair procedures are vital to the safe, reliable operation of all motor vehicles

as well as the personal safety of those performing the repairs. Standard safety procedures and precautions (including use of safety goggles and proper tools and equipment) should be followed at all times to eliminate the possibility of personal injury or improper service which could damage the vehicle or compromise its safety.

Although this material has been prepared with the intent to provide reliable information, no warranty (express or implied) is made as to its accuracy or completeness. Neither is any liability assumed for loss or damage resulting from reliance on this material. SPECIFICALLY, NO WARRANTY OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER WARRANTY IS MADE OR TO BE IMPLIED WITH RESPECT TO THIS MATERIAL. In no event will ECS Tuning, Incorporated or its a liates be liable for any damages, direct or indirect, consequential or compensatory, arising out of the use of this material.