Introduction:

You might ask, why install wheels with different offset and backspacing? There are two reasons; for performance, and for looks. Wider tires and an increased track width can create a dramatic improvement in traction and handling, and many cars simply look better with larger and wider wheels and tires, especially when looking for an aggressive stance. So whether you are improving the looks of your car or modifying your suspension for performance on the track, there are many different reasons that you may want to change the wheel offset and backspace from the factory original measurements. The key to making these changes is to understand how and why to make them. We’ll go over how to measure and determine your current measurements and how to determine what you need for your application. We’ll also cover the advantages and disadvantages of each, giving you everything you need to get the right wheels for your car.

Wheel Offset and Backspacing, while two different measurements, are both equally as important and are used in conjunction with each other. When you know one, you can calculate the other. It is very important to understand both and to consider both measurements when determining the best wheel for your car.

General Preparation and Safety Information:

ECS Tuning cares about your health and safety. Please read the following safety information. This information pertains to automotive service in general, and while it may not pertain to every job you do, please remember and share these important safety tips.

- Park your car in a safe, well lit, level area.

- Shut the engine off and remove the key from the ignition switch.

- Make sure any remote start devices are properly disabled.

- Always wear safety glasses.

- Make sure the parking brake is applied until the vehicle is safely lifted and supported.

- If using an automotive lift, be sure and utilize the factory specified lift points. Lifting a vehicle in an incorrect location can cause damage to the suspension/running gear.

- When lifting a vehicle using a jack, always utilize the factory specified lift points. Lifting a vehicle in an incorrect location can cause damage to the suspension/running gear. Always support the vehicle with jack stands.

- Always read and follow all safety information and warnings for the equipment you are using.

Never get underneath a vehicle that is supported only by a jack. Always make sure that the vehicle is securely supported on jack stands.

Understanding Wheel Offset and Backspacing:

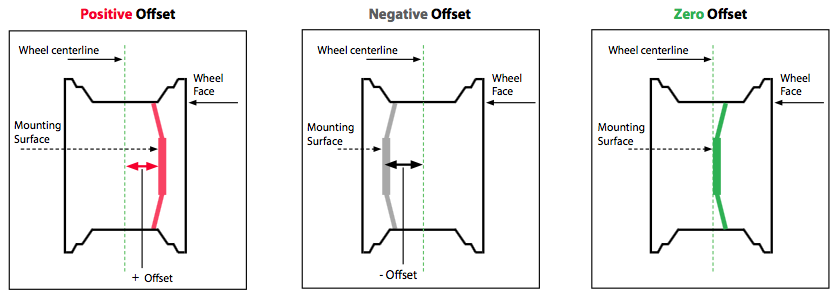

Wheel offset is a measurement that indicates the position of the wheel mounting surface in relation to the wheel centerline. Measured in millimeters, it will be either positive, negative, or zero. Positive offset results when the mounting surface is towards the wheel face, or outside of the wheel. Negative offset results when the mounting surface is towards the back, or inside of the wheel. Zero offset results when the mounting surface of the wheel is even with the centerline.

Most wheels will have the offset measurement stamped into the wheel, usually preceded by the letters “ET”. The abbreviation “ET” originates from the German word for offset, “Einpresstiefe”. An example of a common offset measurement would be “ET30”, which would indicate a positive offset of 30 millimeters.

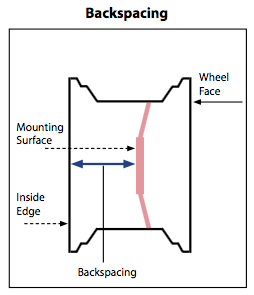

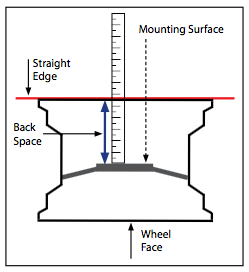

Backspacing is a measurement that indicates the distance between the back, or inside edge of the wheel and the mounting surface. Generally measured in inches, it is a single measurement always indicated as a positive number.

You might ask why there are two different measurements? Backspacing is still a common term and in widespread use, but primarily for wheels that are designed for older American cars and trucks. As the American car industry grew from the 1950’s through the 1980’s, not much changed in the way of suspension and steering technology. Almost everything had a solid rear axle and an A-arm front suspension with spindle mounted drums or rotors. There were very few changes in wheel diameter and width. The most common, and practically the only modification that most people did was putting wider wheels and tires in the rear to get more horsepower to the ground. Since the overall body structure was very similar between all makes and models, the only concern you had was if wider tires would rub on the inside. As a result, you only needed to measure the inside clearance, and American aftermarket wheel companies provided us with the backspacing measurement we needed. There were generally only a couple different choices of backspace for any given wheel, and that was all that was needed to get the right fit for your car.

The term “offset” has always been the standard in Europe. As the European car industry grew through the mid-1900’s, much more emphasis was put on the handling characteristics of the cars they produced than American cars of the same time. Europe was a series of twisty, winding roads and tight spaces, much different than the wide open long straight roads of America. Wheel offset was just one of the critical dimensions built into the steering and suspension design of these cars, and all components were designed to work together. As the European car market became widespread in America, it brought with it suspension technology and European design principles. Along with the desire for superior handling, we have adopted the terminology that goes along with it, and “Offset” is now part of our everyday language.

When you know the wheel backspacing and wheel width, you can calculate offset. When you know the offset and wheel width, you can calculate backspacing.

In this example, the wheel width is 8” and the backspace is 4.75”. We can easily calculate that the wheel centerline is at the 4” mark. Since backspacing is always measured from the inside edge of the wheel, we know that the mounting surface is .75” past the centerline towards the wheel face or an offset of positive .75”. Since there are 25.4mm in an inch, we multiply 25.4 x .75 and get 19.05mm positive offset.

In this example, the wheel width is 8.5” and the offset is positive 35mm. We can easily calculate that the wheel centerline is at the 4.25” mark. If we divide 35mm by 25.4, we get 1.38 inches. We then add 1.38” to 4.25” and we get a backspace measurement of 5.63”.

To measure backspacing, place a straight edge across the inside edge of a wheel, then measure straight down to the wheel mounting surface.

If you don’t know the offset of your wheel, simply measure the backspacing then you can calculate the offset.

Even though there are some advantages and benefits of making changes to wheel offset and backspacing, there are some disadvantages as well. Installing wheels that do not fit a vehicle correctly can cause a number of problems, including safety concerns. If you have any question as to what is safe on your car, consult with a professional automobile service shop.

Advantages of changing wheel offset and backspacing:

- Increased Track Width for improved handling.

- Increasing the Track Width by decreasing positive offset creates more room inside the fender, allowing for wider wheels and tires, providing greater traction.

- Creates awesome looks and an aggressive “stance” for your car.

Disadvantages of changing wheel offset and backspacing:

- Increased steering effort.

- Accelerated tire wear.

- Increased steering sensitivity to road shock.

- Differences in traction on opposing sides.

- Increased bearing wear.

- Increased wear on ball joints, tie rod ends, and suspension bushings.

- Fender clearance issues can arise.

- Inner fender clearance issues can arise.

As you can see, it’s easier to stack up the disadvantages so take your time in determining which wheels are correct for your car. Selecting the correct wheels can benefit you without any negative effects.

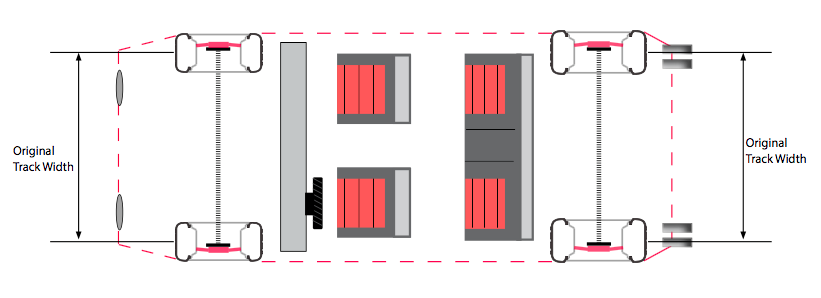

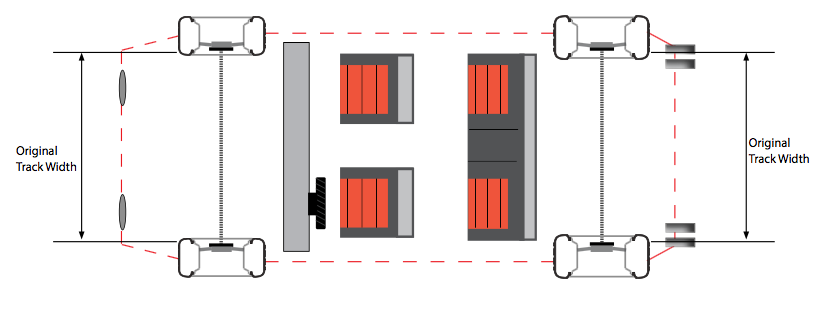

Here are some examples to give you a visual representation of changing wheel offset and the position of the wheel in relation to the suspension and body of a car.

Most modern vehicles are designed with wheels that have a positive offset, so we will begin in this example with positive offset wheels on our car. The wheels sit inside the fenders of the car in both the front and the rear. Notice also the track width measurement (the distance between the centerline of the two wheels on the same axle).

In this example, we have installed wheels with a zero offset on our car. Notice how the wheels are sitting further out. This increases the track width, but can also cause problems with fender clearance and interference.

In this example, we have installed wheels with a negative offset. You can see the extreme difference in wheel position and track width.

Measuring Tools and Kits:

When determining the correct wheels for your car, if you do not have any wheels to test for fitment, there are some different tools that can be used.

The WheelRite tool shown on the right bolts onto your vehicle’s hub to precisely simulate bolt pattern, wheel diameter, wheel width, backspacing, and tire profile. The WheelRite tool is available on our website as ES#2770120.

Wheel spacers can be used to effectively change the backspacing and offset of a wheel. This wheel spacer kit, available from ECS Tuning, will allow you to test fit different thicknesses of spacers so you can order the correct ones the first time. It is on our website as ES#2784343.

Wheel Spacers:

Wheel spacers can be used for a number of different reasons:

1. To make fine adjustments to the ET/offset of a wheel.

2. To change the position of your original wheel in the wheel well.

3. To correct for minor clearance issues.

When using wheel spacers, don’t forget that longer bolts or studs may be required.

Proper service and repair procedures are vital to the safe, reliable operation of all motor vehicles

as well as the personal safety of those performing the repairs. Standard safety procedures and precautions (including use of safety goggles and proper tools and equipment) should be followed at all times to eliminate the possibility of personal injury or improper service which could damage the vehicle or compromise its safety.

Although this material has been prepared with the intent to provide reliable information, no warranty (express or implied) is made as to its accuracy or completeness. Neither is any liability assumed for loss or damage resulting from reliance on this material. SPECIFICALLY, NO WARRANTY OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER WARRANTY IS MADE OR TO BE IMPLIED WITH RESPECT TO THIS MATERIAL. In no event will ECS Tuning, Incorporated or its a liates be liable for any damages, direct or indirect, consequential or compensatory, arising out of the use of this material.