Required Tools:

Flex Driver For Screw Type Hose Clamps*

Phillips Screwdriver

Torx T25 bit

Torx T30 bit

3/8” ratchet

1/4” ratchet with 6” extension

5mm Allen socket

Spring clamp pliers (or locking plier)

Schwaben VAG connector tool*

*Available at ECStuning.com

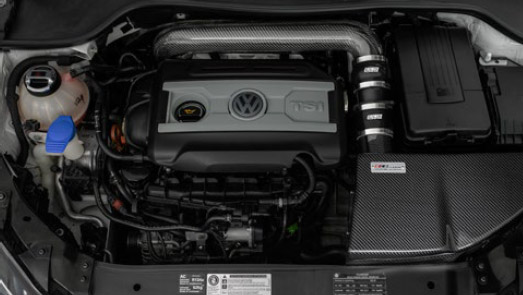

Before Installation, familiarize yourself

with the ECS Tuning MKVI 2.0T Carbon

Fiber Intake Kit

(1) Carbon Fiber Airbox

(1) Carbon Fiber Lid

(1) ECS Tuning High Flow Air Filter with clamp

(1) Carbon Fiber Air Filter Tube

(1) Carbon Fiber Turbo Inlet Tube

(4) Stainless Hose Clamps 65mm-89mm

(2) Stainless Hose Clamps 59mm-83mm

(5) 6mm Bolts with nylon washer 10mm long

(1) 6mm Bolt with large stainless steel

washer 15mm long

(2) Airbox grommets

(1) 3” Straight Coupler

(1) 3” Hump Coupler

(1) 2-3/8” Straight Coupler

(1) 4mm short Allen key

*Kit for CBFA adds:

(1) Filter for Secondary Air Pump

(1) Filter Clamp

-

ECS Tuning Aluminum Filter Adapter

1 Carbon Fiber Air Box and Lid

2 ECS Tuning High Flow Air Filter with clamp

3 Carbon Fiber Air Filter Tube

4 Carbon Fiber Turbo Inlet Tube

5 3” Straight Coupler

6 3” Hump Coupler

7 2-3/8” Straight Coupler

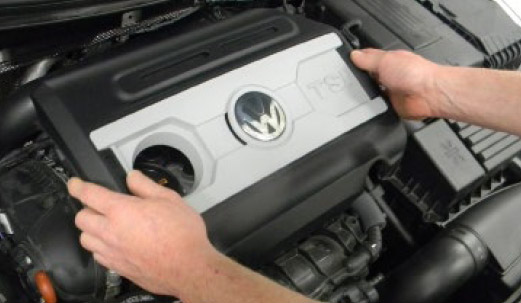

Step 1

Remove the engine cover by

pulling up on the front two corners until

the front grommets release, then pull

up on the rear two corners until the rear

grommets release. Lift the cover off and

set it aside.

Step 2

Remove the two T25 Screws that

secure the original intake duct to the

radiator core support.

Step 3

Separate the intake duct from the adjoining

intake tube by pulling the two pieces apart.

Step 4

Disconnect the mass air flow sensor by

releasing the locking tab on the connector.

Use the Schwaben VAG connector tool

(ES2628676) to release the clip.

Insert the tool into the MAF connector as

shown, and gently pull back on the tool to

release the connector.

Step 5

Pull the mass air flow wiring harness out

of the retaining clip on the back of the

intake connecting pipe.

Position the harness out of the way.

Step 6

Fully loosen the 8 Phillips head screws

that hold the original air box lid to the

original lower air box.

Once loosened, these screws will remain

in the airbox lid. It is not necessary to

completely remove them.

Step 7

Remove the injection intake pipe by

squeezing the two tabs together

Step 8

Pull the air injection pipe off of the air box

lid, and set aside away from your

workspace.

Step 9

Using the special spring clamp pliers,

release the tension on the spring clamp

holding the connecting pipe to the main

intake tube. Slide the spring clamp onto

the connecting pipe and leave the spring

clamp pliers in place.

Tech Tip: If you do not have spring clamp pliers, you can use

channel locks or standard pliers to release the tension on these

clamps. If you do so, be very careful. The clamps can spring off

and cause serious personal injury or damage to your car.

Separate the connecting pipe from the

main intake tube by pulling it off the tube.

Step 10

Lift the airbox lid up and remove it with the

mass air flow sensor and connecting pipe

still connected.

Remove the spring clamp along with this

assembly, then carefully slide the spring

clamp off of the end of the connecting pipe,

and using extreme caution, release the

tension on the clamp.

Step 11

Using the same caution and method from

page 8, release the tension in the spring

clamp holding the connecting pipe to the

mass air flow sensor.

Step 12

Pull the connecting pipe and spring clamp

off of the mass air flow sensor.

Carefully slide the spring clamp off of the

connecting pipe, and using extreme

caution, release the tension in the spring

clamp.

Step 13

Using a T25 Torx bit, remove the two

screws holding the mass air flow sensor to

the original airbox lid.

Pull the mass air flow sensor out of the air

box lid.

Step 14

Using a 5 mm Allen bit on an extension,

remove the bolt holding the lower air box in

place.

Step 15

Using both hands, lift up on the lower air

box to release the two insulating grommets.

Step 16

Pivot the lower air box around the coolant

air bleed hose and remove it from the car.

Step 17

Using a T30 Torx bit socket, remove the

bolt holding the main intake tube to the

heat shield in the rear of the cylinder head.

Step 18

Remove the crank vent hose on the main

intake tube by pinching the release tabs

together using your thumb and forefinger,

then slide the hose off of the main intake

tube.

Step 19

Using the spring clamp (or locking)

pliers, release the tension on the clamp

holding the main intake tube hose to the

turbocharger.

Note: This clamp is difficult to access. This picture shows

the main intake tube removed for reference.

Step 20

Remove the main intake tube and hose by

pulling upward on the main intake tube.

Remove the clamp with this assembly.

Using caution, remove the spring clamp and

release the tension on the clamp.

Step 1

Slide the 2-3/8 straight coupler onto the

turbo end of the carbon fiber turbo inlet

tube.

Step 2

Install one of the 59mm-83mm hose clamps

on the top of the 2-3/8 coupler and tighten it

using a flex driver for screw-type hose clamps.

Use caution not to overtighten.

While the flex-driver is the preferred tool for

this step, a 7mm socket on an extension will

suffice. Take extra caution to avoid marring the

carbon fiber surface.

Flex Driver For Screw Type Hose Clamps

ES5013

Step 3

Place the other 59mm-83mm hose clamp

over the 2-3/8 coupler and install the turbo

inlet tube/coupler assembly onto the

turbocharger.

Step 4

Tighten the lower hose clamp using the flex

driver.

Tech Tip: Some brackets may be in hard to reach

places. You may wish to use a small socket or flex

driver tool for screw type hose clamps.

Step 5

Connect the crankcase ventilation hose by

pushing it into place on the turbo inlet tube.

Step 6

Install the bolt holding the carbon fiber

turbo inlet tube to the heat shield on the

rear of the cylinder head.

Note: For Jetta GLI it may be necessary to adjust the

mounting tab on the heat shield approximately

20 degrees for proper clearance.

Step 7

Tighten the bolt using a T30 Torx bit socket

and ratchet.

Step 8

Place one of the 65mm-89mm clamps over

the end of the 3” hump coupler and push

the coupler onto the carbon fiber turbo inlet

tube.

Do not tighten the clamp at this time.

Note: Pay attention to the location/direction of the clamp

screw. All 4 clamps should be installed with the clam

screw in the same direction for ease of access as well

as uniform appearance.

Step 9

Connect the mass air flow sensor

connector to the mass air flow sensor by

pushing it on until you hear the faint “click”

with the connector locking tab engaging.

Step 10

Place one of the 65mm-89mm clamps over

the remaining end of the 3” hump coupler.

Push the mass air flow sensor into the 3”

hump coupler. Do not tighten the clamps

at this time.

Note: Pay attention to the arrow on the mass air

flow sensor to make sure it is installed in the correct

direction. The arrow points in the direction of air

flow (to the engine).

Step 11

Insert the secondary air pipe adapter into

the air pipe filter and tighten the clamp.

Step 12

Attach the air pipe filter and adapter to the

secondary air pipe, and secure

underneath the air box.

Note: You must choose an optimal location for the

secondary air pipe filter – the unit should be

supported such that it does not move around freely

in the engine bay, and has some access to air flow.

Our filter was secured under the airbox with a

zip-tie, proving to be an adequate location.

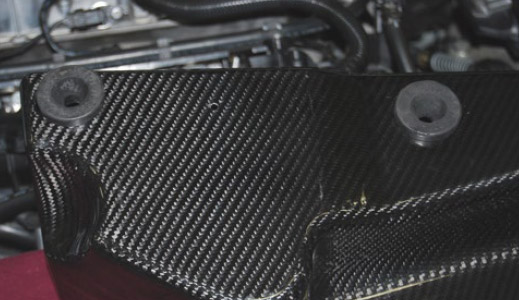

Step 13

Install the 2 grommets into the bottom of the

carbon fiber airbox.

Step 14

Align the carbon fiber airbox and duct, and

push down on the carbon fiber airbox

until the grommets are seated in place.

Step 15

Using a T25 Torx bit, install and tighten the

two screws that secure the carbon fiber air

box duct to the radiator core support.

Tech Tip: A small amount of grease placed on the tip of

the Torx bit will hold the screws in place and keep them

from falling off.

Step 16

Slide the ECS Tuning high flow air filter

element with the clamp in place onto the

carbon fiber air filter tube.

Hold the air filter and tube in place in the

carbon fiber airbox to adjust the position

of the filter. Do not tighten the clamp at this

time.

Note: Use the mounting tab of the air filter tube as a

reference point in determining the correct location of the

filter. Make sure the air filter seam is at the bottom of the

filter.

Step 17

Lift the air filter and carbon fiber air filter

tube out and fully tighten the clamp on the

air filter.

Step 18

Install the 3” straight coupler onto the end

of the mass air flow sensor.

Step 19

Place both remaining 65mm-89mm hose

clamps over the 3” straight coupler.

Do not tighten the clamps at this time.

Step 20

Insert the carbon fiber air filter tube into

the 3” straight coupler.

Step 21

Be sure the Air Filter Tube to Air Box seals

remain in place during installation.

Step 22

Loosely install the 15mm long Allen bolt that

secures the carbon fiber air filter tube in

place.

Step 23

Carefully adjust the carbon fiber air filter tube,

the mass air flow sensor, and both couplers

so everything is aligned nicely and both

couplers are properly seated.

Tighten all 4 hose clamps, paying attention to

the alignment of the clamps in order to obtain

a clean and neat appearance.

Step 24

Tighten the air filter tube securing bolt and

stainless steel washer using a 4mm Allen

socket. A ratchet extension can be helpful

here.

Step 25

Place the carbon fiber airbox lid on top of

the carbon fiber airbox.

Be sure the Air Filter Tube to Air Box seals

are still properly in place during installation.

Step 26

Remove the battery cover by pushing the

release tab in the direction of the arrow on

the cover and lifting upwards.

Note: Removing the battery cover will allow you to more

easily access to the 2 screws on the back side of the

carbon fiber airbox lid.

Step 27

Loosely install all 5 Allen screws

with black nylon washers through the holes

in the carbon fiber air box lid, into the air

box.

Step 28

Using the included short 4mm Allen key,

hand tighten all 5 screws, securing the

carbon fiber air box lid to the carbon fiber

air box.

Be careful not to over tighten these screws,

or you risk cracking the carbon fiber or

stripping the threads.

Step 29